FAQs

**What is VCI?**

VCI stands for **Volatile Corrosion Inhibitor**, which refers to **a corrosion inhibitor that volatilizes**.

VCIs are **organic salts derived from amines**, which gradually volatilize, saturating the internal environment of the packaging. These salts then deposit onto the metallic surface, forming an **invisible monomolecular layer** that protects against corrosion.

When the packaging is opened, this protective layer **immediately dissipates**, leaving the metal **clean and ready for use**.

Manufactured with proprietary technology to provide specific protection for each type of metal, the Volatile Corrosion Inhibitors (VCI) from VCI Brasil are **non-toxic** and **pose no risks to health or the environment**.

**Mechanism of Action of VCI on Metallic Surfaces**

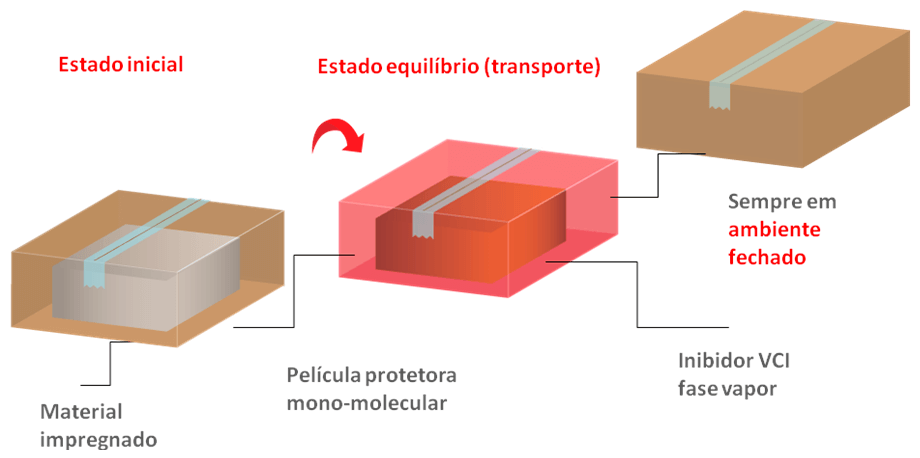

The action of VCI (Volatile Corrosion Inhibitor) on metallic surfaces follows this process:

1. Sealing of the packaging containing the VCI.

2. Volatilization of the VCI.

3. Closed atmosphere containing the VCI.

4. Migration of the VCI to all cavities and areas of the metal piece.

5. Condensation of the VCI on the metallic surface.

6. Absorption of the VCI onto the metallic surface.

7. Formation of a monomolecular layer on the metallic surface.

8. Neutralization of corrosion currents.

9. Saturation of the medium with VCI (equilibrium).

**Protective Mechanism: Formation of a Uniform Monomolecular Film**

The VCI mechanism provides two primary protective effects:

– **Barrier Formation:** Prevents the contact and action of oxidizing agents on the metal surface.

– **Current Neutralization:** Neutralizes polarization currents, effectively halting the oxidation process.

**Advantages of V-active Technology**

– No material deposition on the metallic surface (**Clean Technology**).

– Eliminates the need for post-cleaning processes (no toxic organic solvents required).

– Metallic parts retain excellent visual presentation after storage and transport, ready for immediate use.

– Simple application with high flexibility.

– Provides chemical and mechanical resistance.

– Cost-effective: reduces the number of steps in metal packaging and unpacking processes.

– Poses no risk to human health or the environment, supporting “clean” processes.

– Biodegradable, virtually non-toxic, with some products being recyclable.

**V-active: The Evolution of VCI (Volatile Corrosion Inhibitor)**

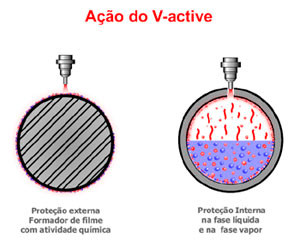

V-active represents the evolution of **VCI (Volatile Corrosion Inhibitor)**, offering the latest advancements in synthesized organic inhibitors developed by the company. It delivers exceptional performance in both contact and vapor phases. Its name reflects its active properties and the ability to migrate between compounds without compromising the stability of its formulations.

**Key Features of V-active:**

– A unique molecular structure that ensures safety for both people and the environment.

– Maintains activity on applied substrates, including paints, resins, varnishes, plastics, process fluids, and cellulose-based products, among others.

V-active is the ideal choice for sustainable and effective corrosion prevention solutions.

**V-active: Effective Action on Metals**

V-active operates effectively in the presence of metals, both in the vapor phase and through contact. It disrupts electrical activity, stabilizing the metallic surface and providing superior protection.

Discover – What Are the Advantages of V-Active?

- Preferred bonding with most metals, including residues, rendering them inert.

- Proven long-lasting presence of the active inhibitor on the surface.

- Anti-corrosive safety for users during internal logistics operations.

- Free from chemical substances listed on international negative lists of hazardous chemicals.

ADITIVO PARA HIDROJATEAMENTO NA SUPERFÍCIE DE METAL

Expostas a diversos fatores que as deterioram e comprometem a aparência, materiais de composição metálica localizados ao ar livre, no mar, ou próximos dele, estão permanentemente necessitando reparos em suas camadas externas, principalmente. Realizar periodicamente uma higienização destas estruturas de aço, exige técnicas especiais e seguras, tanto para as pessoas quanto para as estruturas, sendo que uma delas é o hidrojateamento, com as seguintes características:

Uso de aditivo para hidrojateamento com inibidor de corrosão para metal

Segurança entre o tempo de limpeza até a realização da pintura, sem ocorrência de oxidação na superfície, devido à ação do aditivo para hidrojateamento

Técnica rápida e econômica para trabalhos difíceis e superfícies extensas (cascos de navio, por exemplo)

aditivo para hidrojateamento base água que não polua o meio ambiente

Na remoção da ferrugem, utilizando o produto com um aditivo para hidrojateamento da VCI Brasil, que é opção de produto com alto valor agregado, evita-se uso de químicos, altamente perigosos e poluentes, e de processos mecânicos que podem ferir/danificar a camada externa do metal, exigindo reparos custosos.

ADITIVO PARA HIDROJATEAMENTO COM INIBIDOR DE CORROSÃO – BASE ÁGUA

Usando um aditivo para hidrojateamento contendo inibidor de corrosão, com propriedade retardadora da ação da ferrugem sobre o metal, as vantagens aumentam e você tem mais tempo para proteger o material com a nova camada a ser empregada, seja ela tinta, verniz ou outra de sua preferência. O aditivo para hidrojateamento MVSQ 1712, V-active, VCI Brasil, atribui ao metal uma película de proteção pós lavagem hidrojato com estas características e é indicado para:

- tubulações e metais, metalurgia;

- serviços pesados de limpeza, remoção de incrustações e tintas;

- fornos de refinaria, tanques industriais;

- indústria naval, plataformas de petróleo, petroquími

ADDITIVE FOR HYDROBLASTING ON METAL SURFACES

Metal structures exposed to various deteriorating factors, especially those located outdoors, at sea, or near marine environments, frequently require repairs to their external layers. Regular cleaning of these steel structures demands specialized and safe techniques for both the personnel and the materials, one of which is hydroblasting. This method features the following characteristics:

– Use of **additive for hydroblasting** with corrosion inhibitors for metal.

– Protection against oxidation during the time between cleaning and painting due to the action of the **additive for hydroblasting**.

– A fast and cost-effective technique for challenging tasks and large surfaces (e.g., ship hulls).

– Water-based **additive for hydroblasting** that is environmentally friendly.During rust removal, utilizing a product with a **hydroblasting additive** from VCI Brasil offers a high-value solution that avoids the use of hazardous chemicals and mechanical processes that might damage the metal’s surface, reducing costly repairs.

WATER-BASED HYDROBLASTING ADDITIVE WITH CORROSION INHIBITORS

Using a **hydroblasting additive** containing a corrosion inhibitor with rust-retarding properties enhances the benefits of this method. It extends the time available to apply a protective layer, such as paint, varnish, or other finishes. The **MVSQ 1712** V-active additive from VCI Brasil creates a protective film on the metal surface after hydroblasting, offering these characteristics and is recommended for:

– Pipes and metals in metallurgy.

– Heavy-duty cleaning tasks, including removing scale and paint.

– Refinery furnaces and industrial tanks.

– Naval industries, oil platforms, and petrochemical facilities.The **MVSQ 1712** V-active additive is an organic product. After its application, painting can proceed seamlessly, as it even enhances paint adhesion, eliminating the need for removal before painting.

KEY BENEFITS

– Provides oxidation protection for up to 48 hours before the next protective layer is applied.

– Enables “indoor” storage of the treated metal.

– Suitable for multiple industries and heavy-duty tasks.This **hydroblasting additive** is a comprehensive solution for preserving metal surfaces, simplifying processes, and ensuring long-term protection. Contact VCI Brasil for more information.cas.

Para dizer mais deste aditivo para hidrojateamento MVSQ 1712 V-active, sua composição é orgânica e, após seu uso no metal, a pintura pode ser realizada sem problema algum, pois ele até mesmo auxilia na fixação. Portanto, não precisa ser retirado para aplicação da tinta.

A segurança contra oxidação que este aditivo para hidrojateamento concede é de 48 horas até que a superfície venha a receber a camada de proteção seguinte. O metal deverá ficar estocado “indoor”.

ANTI-CORROSIVE OIL ADDITIVES FOR MACHINES IN THE OIL & GAS INDUSTRY

**Oil additives** are essential supplements in environments where industrial oils are used, ensuring stability and integrity over time.

Machines and equipment in the oil and gas industry, as well as in sugar mills and other sectors, rely on industrial oils to function. These range from large-scale machinery to medium and small-sized equipment, each requiring specific classes of **oil additives** tailored to their motors and operational demands.

The **oil additives** with anti-corrosion inhibitors from the V-active technology, developed by the Brazilian multinational VCI Brasil, are specifically designed to preserve industrial oils during maintenance and hibernation periods, including:

- **Lubricating oil additives**

- **Hydraulic oil additives**

- **Transmission oil additives**

WATER/OIL-BASED ORGANIC ANTI-CORROSIVE ADDITIVES – V-ACTIVE

Atmospheric water is a significant issue for fuels, especially oils. To address sludge formation in engine compartments, particularly those using diesel oil, VCI Brasil has developed **organic oil additives**, such as the water- and oil-soluble **MSQ 1021**, specifically designed for diesel.

The V-active technology ensures that the anti-corrosion inhibitor acts both where the oil contacts the metal surface and in areas where it does not, making it unnecessary to fill the entire compartment. It prevents bacterial growth, preserves the chemical properties of the oil, and protects equipment for extended periods.

Notably, in this technology, water acts as a facilitator, serving as a transport medium for the anti-corrosion inhibitor. This means the technology not only tolerates water but also mitigates its adverse effects on oil.

The **MVSQ 1061 additive**, an organic V-active composition, provides the same anti-corrosion security for various industrial oils. It is mixable with manufactured oils and oil-based solutions but is not water-miscible. However, its corrosion inhibitor functions both in contact and vapor phases.

For equipment, machinery, metal parts, or any assets requiring preservation or anti-corrosion solutions, VCI Brasil offers customized projects and expert assistance. Their mission is to provide the best solutions while reducing costs and adding value to clients.

**Contact: 14-2106-6600** to learn more!

HYDRAULIC OIL ADDITIVES FOR MAINTAINING IDLE EQUIPMENT

**Hydraulic oil additives** are excellent supplements to hydraulic oils, which already contain components designed to reduce the strain on heavy-load motors and lubricate internal system parts.

However, when dealing with idle equipment, **hydraulic oil additives** serve a more specific purpose. They enhance existing properties of the oil, such as lubrication and anti-corrosion, intensifying these benefits. For example:

Antioxidant Properties

One of the anti-corrosion **hydraulic oil additives** from VCI Brasil, **MVSQ 1061**, is specifically formulated for industrial oils used in hibernating machinery. This additive features an organic composition, which ensures compatibility with various environments. It does not damage plastics, rubber, seals, or hoses within systems and equipment.

HYDRAULIC OIL ADDITIVES TO PREVENT CORROSION IN IDLE MACHINES AND MOTORS

**Hydraulic oil additives** containing corrosion inhibitors are essential for maintaining oil-driven machinery and motors (prone to water contamination) during periods of inactivity. These are especially critical in industries with seasonal operations, such as oil & gas, sugar and ethanol mills, and petroleum industries. They provide internal protection for the equipment and fuel, ensuring that operations resume smoothly after downtime.

VCI Brasil recommends these **hydraulic oil additives** to prevent business losses and add value to operations by protecting machinery. **MVSQ 1061, V-active**, not only provides lubrication and anti-oxidation but also forms a protective film on metal surfaces, shielding them from corrosion and avoiding cracks and other severe rust-related issues.

DUAL-PHASE HYDRAULIC OIL ADDITIVES

V-active hydraulic oil additives feature dual-phase active corrosion inhibitors: vapor and liquid.

– **Vapor phase:** The additives sublimate and adhere to areas not covered by liquid, forming a protective layer and filling empty spaces.

– **Liquid phase:** These additives prevent corrosion, repel water, and adhere to metal surfaces.

CHOOSE ORGANIC HYDRAULIC OIL ADDITIVES

When selecting **hydraulic oil additives**, opt for organic options. They are compatible with most industrial oils and do not cause issues such as filter clogging or clumping. These additives provide superior performance while maintaining operational efficiency.

ANTICORROSIVE / ANTIOXIDANT LUBRICATING OIL ADDITIVES

In general, lubricating oil additives are chemically composed, and thus called synthetic, so that when added to oils, they improve their properties. Additionally, additives are also used to minimize the undesirable characteristics of formulated oils on the market.

However, there are organic lubricating oil additives, which are longer-lasting and biodegradable – naturally breaking down due to being organic. Among the many benefits they offer, one stands out: environmental preservation.

The most sought-after oil additives on the market, due to concerns in the maintenance of machinery and equipment in industries across various sectors, especially companies that have seasonal shutdowns, are the lubricating oil additives, hydraulic additives, transmission additives, etc.

However, these lubricating oil additives, whether hydraulic, for transmission, or any other type of oil, must possess an essential property for maintaining the oil’s chemical attributes and protecting the equipment against internal deterioration during machinery downtime.

ORGANIC ANTICORROSIVE LUBRICATING OIL ADDITIVES / BACTERIA GROWTH PREVENTION

Here we are talking about VCI Brasil’s organic oil additives with the renowned V-active technology – corrosion inhibitors in two phases: vapor and liquid. They are known and referred to as:

- MVSQ®1021 – a solution for diesel oil additives, specifically.

- MVSQ®1061 – a solution for lubricating oil additives, hydraulic oil, transmission oil, etc. (formulated market oils).

MVSQ®1021 and MVSQ®1061 are solutions for industrial oil additives that guarantee and enhance anticorrosive protection in the internal systems of engines and machinery in hibernation, neutralizing the acidic action of substances present in the oil itself. This ensures that when operations resume, the internal parts will be free of oxidation/rust, as is the most effective case of action of the lubricating oil additives, as guaranteed by MVSQ®1061, featuring V-active technology.

Biological contamination is another concern that VCI Brasil’s organic anticorrosive oil additives eliminate for their clients. Their composition prevents the proliferation of bacteria that form undesirable sludge at the bottom of oil compartments, which cause damage and clogging in nozzles, valves, etc.

A **metal anti-corrosion solution**, commonly referred to as a protective agent, serves the fundamental purpose of safeguarding metal surfaces against frequent and common corrosive actions, such as electrochemical oxidation, which is more prevalent in our daily lives than we may realize. The most suitable **metal anti-corrosion solution** for each product depends on the specific characteristics of the surface being protected, as each has unique chemical properties that must be considered.

In the **metal anti-corrosion** market, various types of multi-metal protective agents are commonly available. However, it is essential to consider the required protection duration—whether short- or long-term. As this market becomes increasingly demanding due to substantial losses caused by corrosion, some manufacturers now offer oil-based **metal anti-corrosion solutions** that provide both corrosion protection and a physical barrier. Water-based solutions, on the other hand, deliver efficient corrosion protection while being environmentally friendly and safe for workers.

HOW TO FIND A METAL ANTI-CORROSION SOLUTION

To select a **metal anti-corrosion solution** that provides the appropriate protection for your specific product, accounts for necessary durations during various production stages, and considers transportation and storage times, it is crucial to partner with a company that has proven expertise and international success stories. VCI Brasil, with its wide range of corrosion prevention solutions, is such a company.

VCI Brasil manufactures both water- and oil-based protective agents using its exclusive V-active technology. This technology includes an active corrosion inhibitor that protects both external and internal surfaces (such as tanks and pipelines). It works through contact or evaporation within enclosed compartments, diffusing the inhibitor across the walls.

ADVANTAGES OF VCI BRASIL’S METAL ANTI-CORROSION SOLUTION

- The most effective corrosion protection available on the market.

- Water-based products certified for biodegradability and oral, dermal, and inhalation toxicity by competent authorities.

- Oil-based products offering both chemical and physical barriers.

- Fluids that form transparent and efficient anti-oxidation films.

- Explore the complete range of protective agents tailored for different types of metals.

INDUSTRIAL ANTI-CORROSION SOLUTION – PURPOSE AND APPLICATIONS

In an environment where material loss due to corrosion accounts for approximately 5% annually, an **industrial anti-corrosion solution** is essential across most market segments. This is especially true for sectors with equipment, machinery, and structures near the sea, exposed to harsh weather conditions, or operating in hostile environments. With the modernization and development of industries such as metalworking, agro-industrial, steelmaking, construction, oil and gas, sugarcane processing, medical, mining, sanitation, and others, the **industrial anti-corrosion solution** has become critical in reducing production costs, maintaining equipment, and ensuring both financial and reputational stability for companies.

An inappropriate **industrial anti-corrosion solution** can lead to unexpected leaks from tanks or pipelines due to surface abrasion, resulting in severe damage to soil, air, water, or human life. Companies are held accountable for environmental damage, whether intentional or accidental, and may face fines or legal action depending on the severity of the situation.

**Industrial anti-corrosion solutions** can take the form of liquid resin coatings, protective oils, or water-based protective fluids with organic compositions. A specialized and technically knowledgeable team, such as the one at VCI Brasil, is crucial for recommending the best **industrial anti-corrosion solution**. With three decades of experience in the anti-corrosion market, VCI Brasil offers the most effective water-, oil-, and solvent-based solutions for protecting industrial equipment across various sectors, including metalworking, steelmaking, oil, sugarcane processing, agro-industrial, metal mechanics, and mining.

FIND HIGH-PERFORMANCE INDUSTRIAL ANTI-CORROSION SOLUTIONS

A proven option for superior productivity and oxidation resistance is the **industrial anti-corrosion** V-active line from VCI Brasil. These fluids adhere to international standards prohibiting toxic substances, ensuring safety and compliance. Easy to apply, they save production time and offer significant benefits, such as:

– Improved equipment availability for production.

– Reduced maintenance needs.

– Lower product consumption.

Explore how VCI Brasil’s anti-corrosion solutions can enhance your operations.

ANTI-CORROSION NCM – V-ACTIVE

Every organization operating under governmental regulations must classify its products according to the standard nomenclature for each sector. This standard is critical for the proper trade of goods. The NCM (Nomenclature for Mercosur) was established to facilitate trade among Mercosur countries. In the anti-corrosion sector, customers can search for **anti-corrosion NCM** to find the product and review its basic composition.

Invoices must include the NCM code for the merchandise. Ensuring the correct NCM code is the only way to guarantee that the product meets your needs. Knowing the NCM code provides not only the product’s origin but also its composition and application. An **anti-corrosion NCM** specifies the product’s classification, such as whether it is water- or oil-based.

ANTI-CORROSION NCM 34.0399.00

An **anti-corrosion NCM** under code **34.0399.00** refers to an aqueous fluid with an anti-corrosion inhibitor enhanced with V-active. These products include:

– Lubricants with high lubricity and cooling properties.

– Degreasers with superior cleaning power and long-lasting protection.

– Protectors that act in both the vapor and liquid phases, shielding internal compartment walls and maintaining liquids free from microbial contamination.

These water-based fluids are environmentally friendly and do not pollute.

NCM 27.1012.30 – V-ACTIVE

The **anti-corrosion NCM** under code **27.1012.30** refers to oil-based products with organic composition. These products form a rust-preventive protective film and a physical barrier over the metal surface. In environments with challenging conditions—such as proximity to maritime atmospheres, adverse weather, high humidity in storage facilities, and other factors—oil-based protection provides extended and more robust oxidation resistance.

VCI Brasil manufactures protective fluids under NCM codes **34.0399.00** and **27.1012.30**, leveraging the V-active anti-corrosion fluid technology. Additionally, under the **27.1012.30** NCM, VCI Brasil offers a fluid capable of transforming the atmosphere in closed environments, such as air and maritime containers, ensuring that susceptible cargo remains in perfect condition during transit.

Visit the VCI Brasil website to explore the complete line of anti-corrosion solutions.

The mere presence of moisture in the air initiates the oxidation process in steel and various metals. This highlights the necessity of using an **anti-corrosion solution for steel** to protect it and maintain its usability across various applications. Beyond air, water poses the greatest threat to steel manufacturers and industrialists who invest heavily in modern facilities and large machines to expedite production. For these stakeholders, an **anti-corrosion solution for steel** is not just necessary—it is crucial for protecting both their production output and machinery, ensuring the longevity of their investment.

The annual loss due to the oxidation of metallic materials is staggering. Estimates suggest that 30% of steel production is allocated solely to replacing losses caused by rust—a colossal waste of raw materials and labor.

NECESSARY EFFICIENCY IN AN ANTI-CORROSION SOLUTION FOR STEEL

When evaluating an **anti-corrosion solution for steel**, protective efficiency is the most critical factor. Corrosion during production, storage, and transport accounts for the largest losses in this industry. Each scenario demands a tailored treatment, but the most effective approach is to plan production processes that keep machines and parts free from oxidation right from the start. This ensures that the final product reaches the customer in perfect condition, ready for immediate use.

ANTI-CORROSION SOLUTION FOR STEEL: SPECIALIZED PROVIDER

The **anti-corrosion solution for steel** market is vast, offering solvent-based, water-based, and oil-based products. Solvent- and oil-based solutions are often avoided when possible due to their environmental impact, high disposal costs, and potential legal liabilities. As a result, water-based solutions are the preferred option whenever feasible.

VCI Brasil, with 28 years of expertise in anti-corrosion solutions, offers a variety of products, including lubricants, degreasers, protectors, and more with antioxidant properties. Their specialized team evaluates your processes to recommend the best **anti-corrosion solution for steel**, always aiming to maximize your return on investment and ensure your well-being.

ANTI-CORROSION SOLUTION FOR WATER – ASSET PRESERVATION

Moisture is one of the leading culprits affecting major industries such as metallurgy, oil and gas, steelmaking and wire drawing, mining, agro-industrial sectors, and more. Wherever moisture exists—and it is ubiquitous—the risk of oxidation poses a significant threat to unprotected metal surfaces and water-contaminated oils.

The absence of an **anti-corrosion solution for water** to protect industrial yards, million-dollar productions of parts, massive oil platforms, storage tanks for cereals, pumps, valves, and pipelines can result in exorbitant financial losses for any company.

WATER-BASED ANTI-CORROSION SOLUTION FOR WATER

The anti-corrosion market is vast, but in the water-based category, VCI Brasil is the leading choice for an **anti-corrosion solution for water**. Using advanced technology with an active antioxidant inhibitor, known as V-active, VCI Brasil redefines the challenges posed by moisture. This innovative approach turns the moisture from humidity into an ally in rust prevention and bacterial control in oils, such as diesel reservoir tanks.

VCI Brasil’s contemporary technology is designed with environmental responsibility in mind. These anti-corrosion products can be used with cutting fluids for machining all metal types, surface protectors, internal protection for concurrent vessels, pressure-washer degreasers, and neutralizers.

OIL-BASED ANTI-CORROSION SOLUTION FOR WATER

Certain harsh conditions call for an **oil-based anti-corrosion solution for water**. This is particularly true for metal parts stored long-term in open spaces, exposed to variable weather conditions such as sun, rain, and significant temperature changes. Under these circumstances, applying an **anti-corrosion solution for water** that forms both a physical and chemical protective barrier is more effective.

VCI Brasil, with extensive experience in manufacturing oil-based protective products, also offers industrial additives for various oils. These products, classified under NCM 38.2499.41, feature V-active antioxidant protection technology with a rare molecular structure that delivers exceptional stability to metals. Explore V-active protective additives today.

ANTI-CORROSION SOLUTION FOR ALUMINUM – ESSENTIAL FOR MACHINING PARTS

It is a mistake to assume that aluminum, being a more noble metal with a natural oxide layer that protects its surface when exposed to air and moisture, does not undergo corrosion or that manufacturers in this market are not concerned with an **anti-corrosion solution for aluminum**.

Aluminum, abundant in nature and capable of undergoing countless recycling processes without losing its chemical and physical properties, experiences varying degrees of oxidation depending on its proximity to marine environments, exposure to harsh weather conditions, or placement in adverse industrial environments. This makes a suitable **anti-corrosion solution for aluminum** essential based on the environment it will encounter.

Modern companies, particularly those in the automotive sector and manufacturers of vehicle bodies, silos, tanks, and household utilities, recognize the exceptional physical and chemical properties of aluminum and increasingly use it in their products.

These industries, characterized by advanced technologies, focus not only on their production equipment but also on minimizing raw material waste—whether ferrous or non-ferrous metals. To this end, they adopt cleaner and more efficient methods that provide a safer, higher-quality environment, achievable only with an **anti-corrosion solution for aluminum**.

WATER-BASED ANTI-CORROSION SOLUTION FOR ALUMINUM

Water-based fluid technology is the cleanest and most innovative solution for machining, degreasing, protection, and neutralization of aluminum. At VCI Brasil, a company specializing in **anti-corrosion solutions for aluminum**, you will find lubricants, degreasers, protectors, and neutralizers composed of organic materials—non-toxic and biodegradable. These products are synonymous with sustainability and success, as they reduce losses in raw materials, rework, and other inefficiencies.

VCI Brasil exclusively manufactures its **water-based anti-corrosion solution for aluminum** under the V-active line. The V-active technology enables the formation of an anti-corrosion layer on the metal surface, providing temporary protection tailored to the needs of each process.

Contact one of our representatives through the website or email us at info@ingles.vcibrasil.com.br.

ANTI-CORROSION SOLUTION FOR IRON IN INDUSTRIAL CORROSION CONTROL

In industrial districts, fields, rivers, seas, or wherever there is an opportunity for business development—provided logistics and infrastructure are tailored to the production reality—there will be companies established with a clear mission to operate in their specific segment.

Brazil ranks among the 15 largest industrial hubs in the world. Where industries thrive, progress follows, but this progress often comes with losses, including environmental damage, health risks, and the most common issue: corrosion. Companies that fail to invest in **anti-corrosion solutions for iron** contribute to a worrying global statistic of losses caused by rust in industrial facilities.

An **anti-corrosion solution for iron** is essential for any industry that values its assets and production, especially those working with metal or steel. Equipment and machinery must be protected with an **anti-corrosion solution for iron**, whether in operation or idle, to ensure longevity. Furthermore, a well-planned production of metal parts cannot tolerate losses due to rust caused by the absence of an **anti-corrosion solution for iron** in the process. Such negligence can result in irrecoverable losses for the company and its stakeholders.

ANTI-CORROSION SOLUTION FOR IRON – INTERNAL/EXTERNAL PROTECTION WITH V-ACTIVE VCI

The location and type of industry are crucial factors in identifying the right **anti-corrosion solution for iron** for each metal. V-active VCI technology offers protection for metallic surfaces both internally and externally, combating oxidation in indoor and outdoor environments. With contact inhibitors and others that act in the air phase, all possessing **anti-corrosion properties for iron**, V-active’s organic aqueous fluids and protective oils are applied in industries located in urban centers and offshore platforms alike.

A preliminary study is recommended by VCI Brasil, the developer and owner of V-active technology, which also manufactures its own products. After recommendations from their chemical specialists, the fluids containing **anti-corrosion solutions for iron** undergo rigorous protective efficacy testing to ensure they meet quality standards and perform effectively in harsh conditions.

VCI Brasil serves industries such as metallurgy, steelmaking, electronics, shipbuilding, sugar mills, mining, home appliances, petrochemicals, and oil extraction. With its fluids and packaging containing **anti-corrosion solutions for iron**, VCI Brasil helps prevent losses due to oxidation. Learn more!

Metal oxidation is a common phenomenon present in our daily lives, appearing in forms as varied as a steel wool sponge in the kitchen sink, the colossal structure of an oil platform, a magnificent bridge, or the infrastructure of a towering skyscraper. The need for an **anti-corrosion solution for oxidation** arises everywhere—from homes and offices to cars and industries—making it an essential product tailored to different types of metals.

Today, there is an **anti-corrosion solution for oxidation** suitable for every consumer, market segment, and metal property. These solutions are offered with varying degrees of impact on the health of workers, companies, and the environment. Conscious choices by business owners are vital since many options exist. It is crucial to select a solution that not only ensures effective protection against oxidation but also provides additional benefits.

MV OIL 800 – WAX-BASED ANTI-CORROSION SOLUTION FOR OXIDATION

The V-active line of organic and oil-based protective solutions from VCI Brasil offers unique surface protection for metals. These imperceptible films provide both chemical protection—preventing oxidation—and physical defense.

The **MVOil 800** is an example of these protective solutions. Its wax-based layer safeguards the metal efficiently for up to 6 months in outdoor conditions. Once removed, the part remains in perfect condition for use. The MVOil V-active line is ideal for large-scale applications requiring protection against aggressive humidity.

MULTI-PURPOSE ANTI-CORROSION SOLUTION FOR OXIDATION – MVOIL 808 V-ACTIVE

An **anti-corrosion solution for oxidation** can address various needs when applied to different objects, as long as the goal is to prevent rust formation. The **MVOil 808 V-active** is perfect for chains with seals, suitable for motorcycles, bicycles, industrial chains, and even household applications.

Available in spray form, it can be conveniently used for:

– Lubricating and protecting window or door hinges against weather damage.

– Silencing and easing the movement of car doors.

– Restoring the smooth operation of gears or equipment that are hard to turn.

These and other everyday uses make it an indispensable tool for protecting against oxidation.

Explore our wide range of anti-corrosion fluids for your specific needs!

BUY ANTI-CORROSION FLUID

An anti-corrosion fluid can be used to prevent corrosion in water, oxide, oil deterioration treatments in tanks contaminated with water, and more. It is common for those in metallurgy and steel industries, such as wire drawing mills and steel plants, to **buy fluid** for machining metals. However, anti-rust fluids have a wide range of applications.

Some fluids used in metalworking help facilitate various machining operations while protecting the parts from oxidation throughout the manufacturing process. By **buying anti-corrosion fluid** for these operations, you ensure that parts remain rust-free from the start to the end of production. If you **buy protective aqueous fluid** for degreasing, you can rest assured that the parts will reach the packaging stage free of corrosion and ready to be shipped in VCI anti-rust packaging.

Other fluids are designed for pipeline protection, acting as dual-phase inhibitors in contact and vapor phases. These are specifically tailored to protect internal surfaces and air within pipes, tanks, or closed vessels. **Buying fluid** for this type of protection requires a technical study by an expert, as calculations are needed to ensure protective efficiency. VCI Brasil has the right team to recommend the best fluid for your business.

BUY FLUID FOR FORMULATED OILS

Referred to as additives or anti-corrosion fluids, these products are added to oils such as diesel, hydraulic oils, lubricants, transmission oils, etc., to protect them from water contamination. These fluids prevent bacterial colonies from forming in oils, maintaining their chemical and physical properties. Industries like sanitation, oil and gas, refrigeration, hydroelectric plants, and power plants commonly require these products.

At VCI Brasil, you can **buy organic fluid** with the confidence that you’re acquiring a product developed with the highest environmental and quality standards. For certain metals or processes, oily products may be more suitable. However, whenever possible, VCI Brasil recommends products with lower disposal costs to minimize environmental liability and potential health risks.

CONCENTRATED DEGREASER – REMOVAL OF VARIOUS IMPURITIES

A **concentrated degreaser**, or detergent, is designed to eliminate impurities such as oils, grease, fungi, encrustations, tar, and more from machinery, floors, engines, metal parts, walls, roofs, ships, and other surfaces. The **concentrated degreaser** can be applied manually or mechanically, depending on the level of contamination and the type of cleaning required.

The cleanliness of an establishment leaves a strong first impression on both workers and customers, fostering a sense of well-being in a clean environment. A **concentrated degreaser** that is biodegradable and non-toxic to people and the surrounding environment is highly desirable. Its efficiency and ease of use make it a preferred choice for clients seeking a fast and practical cleaning solution.

Clean factories ensure better equipment performance and reduce the likelihood of accidents.

The **AF Line 30.03 Agroindustrial Detergent**, part of the VCI Brasil AF Line, is highly recommended for cleaning floors, walls, roofs, industrial equipment, and agricultural machinery. It replaces solvents and removes heavy petroleum residues, mold, fungi, and more. Once dry, it forms a monomolecular anti-corrosion film on the treated surface.

CONCENTRATED DEGREASER WITH ANTI-RUST PROPERTIES – FOR CHAINS

A **concentrated degreaser** with anti-rust properties offers multiple benefits for chains on motorcycles, bicycles, ATVs, and similar equipment. Dirt buildup on chains can lead to increased friction and wear, affecting performance and longevity. Using a concentrated degreaser not only cleans and lubricates the chain but also protects it, extending its life and improving machine performance.

VCI Brasil’s **WB Line V6 Chain Clean/Grease Remover** is a specialized degreaser for motorcycle chains. Try it for optimal results!

SOLVENT-BASED DEGREASING FLUID – WATER-EMULSIFIABLE

VCI Brasil developed the **concentrated degreaser** **MVOil 753**, a solvent-based product that is water-emulsifiable, designed for heavy-duty manual cleaning of metal parts, equipment, and engines. It is a cost-effective solution that can be used either pure or diluted, depending on the level of contamination. This degreaser is a safer alternative to toxic cleaning agents such as diesel oil, gasoline, and kerosene.

WATER-BASED OIL DEGREASER – ORGANIC, BIODEGRADABLE, AND ANTI-CORROSIVE

An **oil degreaser** for removing oil and other greasy residues is ideal for large-scale washing in industrial washing machines, particularly in segmented production lines where the design and production process allow for this cleaning method.

Companies aiming to minimize environmental and labor-related liabilities, reduce the processing time for metal parts, prevent losses due to oxidized materials during storage and transportation, and ensure over 30 days of safe indoor storage for cleaned parts, should explore the **oil degreaser** solutions from VCI Brasil. This globally renowned company, based in São Paulo, offers cutting-edge **V-active** technology.

VCI Brasil provides the following water-based **oil degreasers**:

- MVAqua 200 – V-active

- MVAqua 203 – V-active

These fluids are designed for use in both machines and manual cleaning methods, including immersion and other applications. Dilution ratios are recommended by expert chemists based on the type and degree of contamination.

One of the key features of these **oil degreasers** is their compatibility with rubber, plastic, paint, and other sensitive materials, ensuring that these surfaces remain unaffected during the cleaning process.

OIL-BASED NON-TOXIC ANTI-CORROSIVE OIL DEGREASER

For heavy-duty cleaning of larger areas, such as machinery, heavy equipment, and fixed metal parts, **MVOil 753 V-active**, another **oil degreaser** developed by VCI Brasil, is recommended.

This solvent-based degreaser is water-emulsifiable and specifically designed for tough cleaning tasks involving grease, oil, and other residues on metal parts and surfaces. It effectively replaces toxic cleaning agents like gasoline, diesel, and kerosene, providing a more economical and safer solution. The product can be used diluted or undiluted, depending on the level of contamination.

In addition to their superior cleaning power, V-active degreasers form a protective anti-corrosive film on metal surfaces, preventing oxidation and extending the life of the parts.

Contact VCI Brasil to learn more about their comprehensive range of cleaning and protection solutions.

A high-quality **industrial degreaser** not only meets client needs but also incorporates surfactants that effectively perform their intended function while being environmentally safe and non-harmful to handlers. The ideal degreaser adheres to regulatory standards to establish itself in the market.

INDUSTRIAL DEGREASER – APPLICATION AND PERFORMANCE

From small tasks to large-scale operations, an **industrial degreaser** performs specialized cleaning tailored to various market sectors. These solutions handle demanding cleaning tasks that require chemical and physical action, either in tandem or separately. The most sought-after degreasers are biodegradable, crafted with organic compounds, water-based, and free from hazardous toxic substances, reflecting a commitment to environmental stewardship.

Industries across different sectors demand diverse detergents. Some require anti-corrosion protection to safeguard surfaces post-cleaning, while others focus solely on cleaning, such as washing walls, roofs, and floors, which necessitate different finishes.

Anti-corrosive degreasers, made with environmentally conscious formulations, are a specialty of VCI Brasil. When applied to metal cleaning operations, VCI Brasil’s **industrial degreasers**, known for their V-active anti-corrosion technology, ensure effectiveness in the cleaning process while providing efficient rust protection.

INDUSTRIAL DEGREASER V-ACTIVE – METALWORKING AND OIL & GAS

The most recommended degreasers from VCI Brasil for production lines in the metalworking and oil & gas sectors are **MVAqua 203** and **MVAqua 200**, respectively. These products have demonstrated significant success in multinational companies, not only delivering financial benefits but also rescuing entire production lines hampered by the lack of an appropriate cleaning solution.

VCI Brasil also offers products for **industrial degreasing** in electrical and electronic panel maintenance. The **MVCleaner V-active**, known for its unique multimetal properties, cleans panel contacts, removing any traces of oxidation. It eliminates the need for highly toxic chemicals like perchloroethylene and tetrachloroethylene while leaving an anti-corrosion protective layer on the internal surface of the panel post-cleaning.

Every industrial degreaser offers technical benefits, allowing customers to find a **competitive price for industrial degreasers** in the fluid market, especially when considering protective degreasers like those offered by VCI Brasil.

FACTORS TO CONSIDER FOR THE BEST VALUE IN INDUSTRIAL DEGREASER PRICING

The **price of VCI Brasil’s industrial degreaser** reflects its ability to deliver superior cleaning and protection throughout the processes it supports. This is a value-added concept that the company provides to its clients.

When customers search solely for the **price of an industrial degreaser**, they risk choosing a product that may fail to meet the hygiene standards required for their parts. This can result in leftover particles on the pieces, which could compromise subsequent processes, damage the client’s reputation, or even lead to contract breaches due to defective parts.

ADVANTAGES OF VCI BRASIL’S INDUSTRIAL DEGREASERS

A **competitive price for an industrial degreaser** includes both affordability and performance. The product must clean effectively and protect the item, as is the case with VCI Brasil’s degreasing fluids.

Known as **V-active**, these fluids predominantly use a water base to clean and degrease while leaving a protective anti-oxidation layer on the surface, creating a temporary barrier against rust.

The most popular protective degreasing fluids among VCI Brasil’s customers are:

– **V-active MVAqua 200 and MVAqua 203**: Primarily used in the metalworking industry, offering up to 90 days of indoor protection.

– **MVAqua 200**: Recommended for degreasing in the Oil & Gas industry.

– **MVOil 753**: Suitable for heavy manual cleaning in the steel industry.

VCI Brasil’s **industrial degreasers** also offer a significant advantage: they reduce production steps in metal parts manufacturing.

This innovation boosts market competitiveness by:

– Eliminating unnecessary production steps.

– Reducing labor costs.

– Increasing productivity.

– Lowering fixed production costs.

Furthermore, VCI Brasil’s industrial degreasers ensure a healthier environment for both operators and the industry. Check out their range for a cleaner and more efficient solution!

A **packaging for metal parts** is a product specifically designed for a niche market where it contributes to the overall value of the client’s merchandise. It is essential for ensuring a commitment to quality delivery and readiness for immediate use in the buyer’s production line.

The **packaging for metal parts** requires an analysis of the environment—how and where it is manufactured—to understand the storage conditions, such as humidity levels, and to provide better recommendations for packing, storing, and, if necessary, transportation.

Oxidation remains a primary concern for these business owners, contributing to an annual waste of around 5% due to steel deterioration.

PACKAGING FOR METAL PARTS – CHEMICAL AND PHYSICAL PROTECTION

The most suitable **packaging for metal parts** must provide both chemical and physical protection. This ensures defense against rust and potential impacts during handling and transportation. With these protection principles in mind, VCI Brasil Indústria e Comércio de Embalagens Ltda. has been innovating and manufacturing the most efficient **packaging for metal parts** for nearly three decades, serving both national and international markets.

VCI BRASIL MATERIALS FOR PACKAGING METAL PARTS

The ideal material might be:

– A customized cellulose plate.

– A plastic bag tailored to specific dimensions.

– A raffia mesh treated with VCI Brasil’s volatile corrosion inhibitor (VCI).

The appropriate physical medium is determined by VCI Brasil’s skilled product engineering team, which analyzes the client’s process and merchandise. The material that carries the VCI—acting as a corrosion prevention agent—or that provides physical support for the load is selected based on the conditions the **packaging for metal parts** will face, such as temperature, climate, and logistical challenges.

Of all materials, paper offers the highest protective capability in highly humid environments. As **packaging for metal parts**, paper is recommended for its superior absorption of the inhibitor and ease of recycling. Similarly, VCI-treated plastic from VCI Brasil is suitable for metals based on the conditions they will encounter post-packaging.

For further details, consult VCI Brasil representatives.

**Anti-corrosion packaging** is specifically designed to preserve products in the metal parts manufacturing market, where oxidation poses a significant risk that must be addressed in production planning.

In a not-so-distant past, many metal part manufacturers relied on grease- or oil-based products to protect their production during storage. While the advent of **anti-corrosion packaging** has reduced this practice, some companies still use it, causing unnecessary environmental harm.

ANTI-CORROSION PACKAGING – CLEAN PARTS FOR THE CLIENT

The security that more conservative entrepreneurs once felt in the environmentally harmful use of grease and oil to preserve parts has been challenged. Many have shifted their trust to **anti-corrosion packaging**, particularly after VCI Brasil entered the market. By developing its own VCI (Volatile Corrosion Inhibitor), VCI Brasil demonstrated unparalleled efficiency and performance, ensuring rust protection under various adverse temperature and climate conditions. This led to a significant conceptual shift in the industry: parts became cleaner and ready for use upon delivery to the client, eliminating pre-use cleaning stages. This change reduced waste for all parties, including the environment.

STEEL PROTECTION USING VCI BRASIL’S ANTI-CORROSION PACKAGING

In addition to producing protective fluids and coil and roll packaging machines, VCI Brasil is a manufacturer of **anti-corrosion packaging**. With expertise in creating specialized packaging to prevent rust, VCI Brasil has a skilled team to assess each client’s needs and make the appropriate recommendations.

Based on these recommendations, the ideal type of VCI, the best material (such as paper, laminated or raffia paper, plain or bubble film, stretch or shrink film, laminated or delaminated raffia, cellulose liners, etc.), and the optimal format will be suggested.

It’s important to note that to qualify as **anti-corrosion packaging**, the material must be treated with a volatile corrosion inhibitor. This treatment guarantees protection as long as the packaging remains sealed. Once opened, the protective capability diminishes as the packaging is exposed to air.

Specifically designed to add value to merchandise, **packaging for metal parts** is essential in the ferrous and non-ferrous metals market. Always developed with the challenges the product will face from packing to delivery in mind, **packaging for metal parts** can be made from plastic, raffia, paper, or other physical materials capable of incorporating a corrosion inhibitor for added protection.

Various companies offer a wide range of inhibitors for **packaging for metal parts**. However, it is common to find products containing highly toxic agents, including banned salts such as nitrites and nitrates, along with numerous carcinogenic substances listed in restricted chemical inventories.

VCI BRASIL – QUALITY PACKAGING FOR METAL PARTS WITH VCI

The **packaging for metal parts** from VCI Brasil, recognized for almost 30 years, is chemically treated with their proprietary VCI (Volatile Corrosion Inhibitor). Free from substances harmful to health or the environment, it is one of the most recommended inhibitors in its category.

Whether it is paper, laminated raffia screens, plain or laminated plastics, cellulose sheets, or other materials, the key feature of **packaging for metal parts** lies in the inhibitor they are treated with. This inhibitor must provide the most suitable corrosion protection for the environment in which the packaging will be used. At VCI Brasil, packaging is customized and supplied as sheets, bags, or rolls, depending on the consumer’s needs.

PACKAGING FOR METAL PARTS BY VCI BRASIL WITH ACTIVE VCI

Paper can be plain or reinforced to provide greater versatility or resistance, depending on its intended use. Treated with VCI Brasil’s active volatile corrosion inhibitor, the **Raffia Paper VCI**, for example, offers protection against the harsh and oxidizing marine atmosphere and the physical strength required to withstand the barriers encountered during intermodal transportation for exports.

The **VCI Bubble Film** is ideal for packaging that needs to absorb impacts during cargo handling. VCI Brasil is known for producing bags made from this film, sized to wrap large-volume parts, such as automotive body components and irregularly shaped, heavy, and bulky items, including entire machines.

BUY COOLANT FLUID FOR SPECIFIC METAL TYPES

To achieve reduced temperatures during metal machining, it is essential to **buy coolant fluid** to meet this goal. If the metal can be machined using a water-based coolant fluid, it can further decrease temperatures. However, not all metals are suitable for this due to fire risks during operation, as is the case with magnesium, which must be machined dry.

Buying **coolant fluid** is also crucial for prolonging tool life, maintaining dimensional accuracy of parts, and ensuring optimal performance of machine tools. This product directly affects the tools, machines, and production outcomes.

When choosing to **buy coolant fluid**, liquid options are typically the most preferred due to their lubricating and cooling properties. Gaseous fluids primarily cool, while solid fluids mainly lubricate. However, beyond the state of the fluid, it is fundamental to seek a reputable international manufacturer to ensure quality when you **buy coolant fluid**.

The market offers a wide variety of these products, so careful selection is essential.

COOLANT FLUID MANUFACTURER

VCI Brasil, a Brazilian multinational, is a trusted source for purchasing water-based coolant fluids. These fluids incorporate the innovative V-active anti-corrosion technology, which provides corrosion protection during machining and other processes such as grinding, wire drawing, and rolling. VCI Brasil focuses on combining advanced technology with employee well-being, ensuring productivity and quality without compromising workplace health or the business’s objectives. This also contributes to a cleaner, healthier environment.

VCI Brasil’s V-active innovation uses water to challenge the fear of humidity in metal part production environments. When you **buy coolant fluid** for metal transformation operations, water-based fluids are recommended. For metals that tolerate liquid cooling, water reduces temperature and, in the case of V-active fluids, serves as a carrier for VCI Brasil’s special corrosion-inhibiting active ingredient.

**Buy V-active water-based fluids** to make your company more productive and maintain a healthier working environment.

Degreasers are essential products in the machining operations of metal parts. These products vary in their degreasing power, offering more or less intense cleaning depending on the needs of the production chain in which they will be used.

When deciding to **buy a degreaser**, it is crucial to consider the specifics of the item to be cleaned. For instance, one might **buy a degreaser** for cleaning a mechanical part when a surgical piece requires an entirely different cleaning standard. The cleanliness level required for a part directly relates to the criticality of its application.

Entrepreneurs with less environmentally conscious practices often rely on grease coatings to prevent corrosion during intermediate production stages. This approach demands higher quantities of degreasers and increases disposal costs for grease residues.

Environmentally aware industries focused on saving production time, increasing profits, and minimizing material loss seek to **buy degreasers** with integrated anti-corrosion agents. These degreasers reduce production stages and costs. The most effective degreasing option with anti-rust protection is from VCI Brasil’s V-active line.

BUY V-ACTIVE DEGREASER

At VCI Brasil, located in Bauru, SP, you can find industrial degreasers and a team of experienced professionals ready to conduct studies to recommend the best application for your operational line.

BUY DEGREASERS COMPATIBLE WITH VCI PACKAGING

Metal parts, after machining, often undergo a degreasing process to remove machining residues. Once cleaned, these parts may proceed to another machining operation, storage, or transportation.

If stored with an oily or greasy coating, they cannot be packaged using VCI packaging—VCI Brasil’s solution for protecting parts from oxidation until they are unboxed at their destination. V-active degreasers, compatible with VCI packaging, are available exclusively at VCI Brasil.

If you are looking for a **company specializing in anti-corrosion packaging**, renowned both in Brazil and abroad, not only for manufacturing fluids that protect against rust but also for its excellence in packaging for metallic parts, then you are referring to **VCI BRASIL INDÚSTRIA E COMÉRCIO DE EMBALAGENS LTDA**.

Located in one of the most prosperous regions in the interior of São Paulo state, VCI Brasil is the leading **anti-corrosion packaging company** in the auto parts, automotive, steel, and metal parts industries. This leadership stems from the development of its own volatile corrosion inhibitor (VCI), formulated without harmful elements to the environment and workers.

VCI BRASIL: ANTI-CORROSION PACKAGING COMPANY FOR CKD EXPORTS AND MORE

VCI Brasil was the first **anti-corrosion packaging company** in Latin America to conduct CKD exports, eliminating the use of grease as a protective agent. This ensures that parts arrive at the client’s production line free from residues and oxidation when packaged following VCI’s recommended procedures. In this mode, the most commonly used packaging is made from paper and plastic treated with VCI.

VCI ANTI-CORROSION PACKAGING COMPANY FOR THE STEEL INDUSTRY

The development of machines to package coils and rolls for steel companies has brought this segment closer to VCI Brasil. With registered patents for its packaging machinery, VCI Brasil is an **anti-corrosion packaging company** that places particular focus on the steel industry, especially for coil wrapping. Patented by VCI Brasil, this packaging method is carried out by their machines to ensure better sealing and resistance, which is challenging to achieve manually, particularly due to the size of steel coils.

The packaging materials most commonly used in VCI Brasil’s machines for the steel industry are designed to offer superior physical and chemical barriers. These include raffia, raffia paper, laminated raffia, or delaminated raffia (non-laminated materials), all treated with VCI’s proprietary anti-corrosion technology.

Only an **anti-corrosion packaging company** like VCI Brasil can offer a wide range of VCI solutions in paper, raffia, plastics, cellulose sheets, and more. Find the solution best suited to your merchandise!

**Anti-corrosion companies** focus on sectors that require protection against corrosion. Their offerings include coatings such as paint layers, liquid resins, greases, oils, and aqueous or oil-based fluids containing oxidation inhibitors.

The **anti-corrosion market** is extensive and comprises both national and international companies. While most operate in the general market for metallic parts, some excel with specialized products.

SUCCESSFUL ANTI-CORROSION COMPANIES IN BRAZIL: VCI BRASIL

Among Brazilian **anti-corrosion companies**, VCI Brasil stands out as a prominent multinational leader. Founded in 1990, the company initially focused on the representation and distribution of anti-corrosion papers. By 1992, it began producing its own treated packaging with the development of its proprietary volatile corrosion inhibitor (VCI). Since then, VCI Brasil has introduced cutting-edge technologies and solutions for combating oxidation.

In 1996, VCI Brasil launched its first multimetallic volatile corrosion inhibitor formula, free of nitrite salts. The company’s commitment to clean technology has resulted in products that are free of nitrate salts, boron, nitrites, carcinogenic substances, and heavy metals.

ANTI-CORROSION COMPANIES WITH PROPRIETARY TECHNOLOGY

VCI Brasil is among the **anti-corrosion companies** that develop proprietary technologies through its in-house laboratories and partnerships with international universities. Renowned for its innovative anti-corrosion packaging, VCI Brasil ensures the safe chemical and physical transport of parts and equipment, and it is steadily gaining recognition in the protective fluid market.

The company’s protective fluid technology—used for machining, degreasing, protection, and neutralization—is branded as V-active. This advanced solution acts on metal surfaces through contact and, when applied internally (e.g., in pipelines), releases vapor to provide protection.

VCI Brasil has also established itself in the market for steel coil and wire roll packaging machinery. Among **anti-corrosion companies** serving the steel industry, it is a standout, delivering operational and financial benefits. By collaborating with steel plants, VCI Brasil deploys its machinery and technical teams to enhance packaging quality, significantly reduce material waste, minimize workplace accidents, and lower packaging costs.

**Fluid companies** offer products to meet the diverse needs of various consumers. However, not all fluids provide rust protection or the desired lubricity for machining operations that certain types of metals require. Some **fluid companies**, driven solely by their own survival, may disregard the importance of formulating products with organic bases or minimizing environmental harm.

Fortunately, stricter regulations in some communities regarding the harmful effects of certain products on factory workers’ health have led to positive changes. These regulations encourage **fluid companies** to focus on developing cleaner formulas, free from prohibited substances.

WATER-BASED ANTI-CORROSION FLUID COMPANIES – V-ACTIVE MANUFACTURER

Among the most reputable **water-based anti-corrosion fluid companies** in Brazil, VCI Brasil stands out as the ideal choice for those seeking machining productivity and efficient antioxidant protection for in-process or finished parts. Their cutting fluids and protective agents are water-based, organic, biodegradable, and non-toxic to human health.

While working with water as a base may seem paradoxical in the metalworking industry, VCI Brasil’s technical team discovered that water is a valuable ally in combating corrosion. Products from the V-active line not only eliminate environmental risks but also challenge the misconception that moisture is always detrimental in this sector.

This conceptual shift aligns with VCI Brasil’s commitment to environmental preservation. Products in this line are branded as MVAqua.

OIL-BASED ANTIOXIDANT FLUID COMPANIES – V-ACTIVE MANUFACTURER

In addition to water-based protective fluids, VCI Brasil is one of the leading **oil-based anti-corrosion fluid companies**, focusing on solutions for industries requiring oil-based products due to the extremely hostile environments their metal surfaces face.

VCI Brasil’s oil-based fluids from the V-active line form antioxidant and waxy films—examples include:

– **MVOil 800**: Antioxidant film former.

– **MVOil 802**: Anti-seize.

– **MVOil 807**: Thixotropic.

– **MVOil 808**: Anti-wear.

LOCATION OF VCI BRASIL’S ANTI-CORROSION PACKAGING FACTORY

With over 10,000 m², located in the city of Bauru, in the interior of São Paulo, VCI Brasil is the **anti-corrosion packaging factory** recognized nationally and internationally. Offering solutions ranging from production to logistics, delivering profitable results for clients and consumers alike, VCI Brasil, a Brazilian multinational **anti-corrosion packaging factory**, provides a wide variety of products to combat oxidation.

In its early days in 1990, the company focused on the distribution and representation of anti-corrosion papers. By 1992, with the in-house production of its VCI (Volatile Corrosion Inhibitor), VCI Brasil established its first **anti-corrosion packaging factory**, developing packaging tailored to its clients’ needs and earning the respect of major multinationals.

PACKAGING FORMATS IN THE ANTI-CORROSION PACKAGING FACTORY

The applications for VCI, a volatile corrosion inhibitor embedded in a physical medium, depend on the properties of the chosen material. For example, paper allows for greater VCI absorption per cubic meter. This makes paper one of the most sought-after logistics strategies for those working with an **anti-corrosion packaging factory**.

VCI Brasil produces anti-corrosion packaging in various formats:

– **VCI Paper**: Offers superior antioxidant protection.

– **VCI Laminated Paper**: Combines the protection of VCI Paper with mechanical barrier and impermeability.

– **VCI Raffia Paper**: Provides enhanced barrier properties, impermeability, and rust protection.

For shorter-term protection of metal parts, plastic packaging offers excellent protective performance and greater versatility for packaging. At VCI Brasil’s **anti-corrosion packaging factory**, a variety of anti-rust plastic packaging options are available.

### Examples include:

– **FM8 VCI Stretch Film for Metallurgy**: Widely used in industrial packaging, it combines the strength of high-tech resin compositions with VCI technology from VCI Brasil.

– **VCI Shrink Film**: Shrinks when heated to conform to the shape of the item, features UV resistance, and includes flame-retardant technology.

Discover the active **anti-corrosion packaging factory** solutions at VCI Brasil!

A **manufacturer of anti-corrosion packaging** must specialize in developing solutions for the logistics of packaging and transportation for companies in the metal industry.

While corrosion is a persistent concern throughout the production process of metal parts or equipment, there is room in the market for both specialized **anti-corrosion packaging manufacturers** and for innovators offering broader protective mechanisms. For some, only the end result and profit matter.

For a **manufacturer of anti-corrosion packaging** like VCI Brasil, the focus is on providing a mechanism to solve corrosion issues. This mechanism can involve traditional packaging materials or advanced anti-corrosion systems made from cellulose-based or plastic materials.

LOW-COST SOLUTIONS FROM AN ANTI-CORROSION PACKAGING MANUFACTURER

Take the case of Woodactive, a product from this Brazilian multinational **manufacturer of anti-corrosion packaging**. Even if the customer cannot or does not want to invest in additional protective supplies, simply using a treated wooden box with the Woodactive solution provides essential anti-corrosion protection for the cargo.

Detail: With proper care and adherence to the Woodactive preservation guidelines, the wooden box can keep metal parts protected for an extended period. For greater preservation needs, VCI Brasil, as a **manufacturer of anti-corrosion packaging**, can recommend additional internal packaging for the metal parts. However, the treated wooden box offers a low-cost solution for those using this material for the transport of their final metal products.

VCI BRASIL – ANTIOXIDANT PROTECTION WITH RESIN AND SHRINK WRAP

MVSkin resin, while not a traditional packaging material, is another solution offered by VCI Brasil as a **manufacturer of anti-corrosion packaging**. Solvent-based and widely used in the oil & gas industry, it provides exceptional preservation for metals in harsh environments. It is particularly effective in wrapping multi-shaped parts, leaving a plastic protective layer with anti-corrosion properties.

In some cases, metals require packaging that conforms tightly to their shape, a task only shrink wrap can accomplish. VCI Brasil offers this specialized plastic with anti-corrosion protection, ensuring proper application through its trusted partners. Explore the various packaging and protection mechanisms available with VCI Brasil!

Typically, **degreaser manufacturers** offer solutions for cleaning dirt mostly related to petroleum residues. As a result, these products often contain heavy solvents, making them highly harmful to health and unsuitable for daily use.

Modern culture directs us to seek **degreaser manufacturers** who work with biodegradable liquids, ideally those that are safe for both people and the environment. Such a choice helps care for the industrial environment as well.

BIODEGRADABLE AND NON-TOXIC DEGREASER MANUFACTURERS

Finding **degreaser manufacturers** committed to this new reality is not easy, as it requires a shift in practices not just by the manufacturer but also by the consumer. Consumers who believe in innovation and embrace market advancements are more likely to lead their segments in partnership with cutting-edge suppliers.

Among **degreaser manufacturers**, VCI Brasil is the most modern choice, offering water-based degreasers formulated with organic compounds. These products provide superior biodegradability and are non-toxic to health. They not only clean but also create an anti-corrosion protective barrier on the metal’s outer layer for a specified duration.

MVAQUA DEGREASER MANUFACTURERS

The highlighted MVAqua line from the proven V-active technology by VCI Brasil offers unique solutions and results. These organic and water-based products provide anti-corrosion protection for ferrous and non-ferrous metals.

For use in pressurized part-washing equipment, MVAqua 200 and MVAqua 203 cater to the metalworking industry. The oil & gas sector benefits most from MVAqua 200. Each market requires a detailed study to recommend the best solution, as the entire MVAqua line can be customized to better serve customers.

For manual degreasing, heavy-duty cleaning, or sanitization of surfaces and parts unsuitable for line washing machines, VCI Brasil recommends its MVOil 753 V-active product. Unlike other **degreaser manufacturers**, it replaces diesel, gasoline, and kerosene. Additionally, it is water-emulsifiable.

A **corrosion-inhibiting fluid**, as the name suggests, is a product designed to combat corrosion in environments where it may occur. Here, we focus on **corrosion-inhibiting fluid** for protecting metals, whether at the beginning, during, or at the end of production, including the maintenance of equipment involved in these processes.

Wherever metal is located, it requires protection. In the production of metal parts, starting preservation with a layer of protection is ideal as it provides antioxidant defense from the outset. During machining, metal parts undergo significant changes and become highly vulnerable to rust if they do not receive anti-corrosion treatment when transitioning between processes.

SAFE MACHINING WITH V-ACTIVE CORROSION-INHIBITING FLUID

A **corrosion-inhibiting fluid** for machining is crucial in this context. However, many machining companies make mistakes by using improper anti-corrosion products in these operations. VCI Brasil offers a **corrosion-inhibiting fluid** with the most suitable temporary protection for your product.

Combining experience and technology with their clients’ production processes, VCI Brasil ensures success in intermediate and final product quality, cost reduction, and many other benefits.

The most effective products from the V-active technology for machining, providing protection for a specific period without leaving solid residues on machined parts, include MVAqua 180, MVAqua 182, and MVAqua 150. These products can also be customized based on the metals and environment.

CLEANING AND PROTECTION WITH V-ACTIVE CORROSION-INHIBITING FLUID

Successful cases demonstrate greater control over production stages, sometimes eliminating entire steps, thanks to the efficiency of the **V-active corrosion-inhibiting degreaser** from VCI Brasil.

This line of degreasers with rust protection cleans and safeguards parts long enough for their next destination without requiring additional protection, such as oily layers. These layers are not only unhealthy but also introduce extra cleaning steps into the process.

When prolonged protection between stages is necessary, VCI Brasil’s technical team will recommend a **corrosion-inhibiting fluid** from the same V-active technology. Depending on the type of preservation required, this could include MVAqua 250 or MVAqua 300, compatible with the MVAqua line.

The need for modernization and adaptability to remain competitive has driven large machining companies to adopt the well-known CNC machining centers (Computer Numerical Control). These machines, which come at a significant cost and feature advanced technology, demand the highest level of care in operation and maintenance.

To ensure optimal performance, it is essential to use a **CNC cutting fluid** that is both suitable for the machine and compatible with the operation. These machining centers are highly sensitive and require careful selection of products introduced into their systems to avoid potentially costly technical failures.

SPECIAL CNC CUTTING FLUID FOR MACHINING CENTERS

VCI Brasil, with its expertise in anti-corrosive fluids, has become a benchmark in **CNC cutting fluid** by providing the safety the industry demands. The **CNC cutting fluid** from VCI Brasil aligns with the technical precision that machining centers must maintain. These fluids play a crucial role in enhancing productivity and ensuring the quality these machines deliver.

Without **CNC cutting fluid**, machining cannot function effectively, as the fluid serves multiple purposes:

– Lubricating surfaces to minimize friction and wear between the worked part and the tool;

– Cooling the metal at the machining site;

– Cleaning the machined surface and removing chips;

– Providing anti-corrosion protection.

Examples of **CNC cutting fluid** from VCI Brasil include the innovative aqueous V-active series, such as MVAqua 180, 182, and 150, tailored for specific applications.

CNC CUTTING FLUID AS MACHINE TOOL PROTECTION

Another critical role of **CNC cutting fluid** is protecting the machining center itself. The V-active cutting fluid from VCI Brasil, a water-based protective solution, not only safeguards the worker’s health but also helps preserve the machining center by protecting it against corrosion. The aqueous V-active fluids do not harm the rubber, paint, or seals of these machines.

After machining, the treated part is ready for use. Its application is ensured by the use of a V-active anti-corrosive protection fluid from VCI Brasil, allowing it to be suitable for any situation—whether for a subsequent machining operation on another CNC machine or for packaging with anti-corrosive VCI Brasil products for long-term transport or storage.

A **lubricating cutting fluid**, although readily available in many specialized stores today, is a purchase suited for machining experts. It requires a deep understanding of the metal, the tool that will shape the metal, and the machine responsible for producing the part.

The market offers **lubricating cutting fluid** with anti-corrosion protection, which is the most common, and also without it, which can lead to significant problems for metal part manufacturers.

USING LUBRICATING CUTTING FLUID AS A COST-REDUCTION TOOL

To run a business today, whether small or large, entrepreneurs must carefully manage all costs and resources, aiming to minimize expenses and maximize profits in an increasingly challenging environment.

In choosing a **lubricating cutting fluid**, these adjustments can be achieved by selecting the right product to boost productivity, thereby lowering costs and increasing profitability.

VCI Brasil offers a revolutionary water-based **lubricating cutting fluid**, proven to enhance production quality by delivering unmatched surface finishing. The lubricity required for effective metal removal is an exceptional quality of its composition, directly impacting operational performance while preventing undesirable wear or breakage of tools.

ADVANTAGES OF THE V-ACTIVE LUBRICATING CUTTING FLUID BY VCI BRASIL

The **lubricating cutting fluid** from VCI Brasil, with V-active technology, features an organic and water-based composition and is widely used in major machining operations. It is tested and approved for use in both conventional machine tools and advanced CNC machines.

Its numerous advantages include:

– Up to 70% more parts produced per tool;

– Clean and oxidation-protected production machines;

– Visible parts during manufacturing, allowing for better inspection;

– Lower working temperatures for both parts and fluid;

– Improved tool and machine conditions;

– Extended fluid lifespan due to its bactericidal properties, offering an odorless and stable solution.

Use V-active MVAqua water-based fluids in production lines for machine tools and CNCs. The benefits will be evident from the first operation. Contact the VCI Brasil technical team to learn more!

CUTTING FLUID TO PLAN PRODUCTION AT LOWER COST

For successful machining of aluminum parts, enabling fast production with precise finishing, the use of a **cutting fluid for aluminum** is essential. During product planning, a **cutting fluid for aluminum** becomes a technical item that provides benefits and must be considered for achieving excellent results.

In today’s market, machine tools and CNC machines (Computer Numerical Control) are the most commonly used for producing aluminum parts due to their high cutting speed, precision, lower cost, and faster manufacturing time. To support this performance, metal machining companies seek auxiliary solutions, such as a **cutting fluid for aluminum**, integrating them into their processes to achieve these objectives.

ALUMINUM CUTTING FLUID MVAQUA 180/182 V-ACTIVE VCI BRASIL