Corrosion is a globally recognized challenge with widely acknowledged effects. According to a study conducted by the Zinc Association (IZA), supported by the University of São Paulo (USP), it is estimated that the costs associated with corrosion represent approximately 4% of Brazil’s Gross Domestic Product (GDP).

Imagining about 4% of your company’s revenue being gradually corroded by this problem on a daily basis is, at the very least, a disturbing exercise.

However, what lies beneath the surface is even more impactful. Corrosion is not limited to material degradation and the costs related to the replacement of raw materials. It infiltrates various areas of operations, from logistics costs involving rejected products to labor and machinery expenses for repairs and replacements. Furthermore, there’s the opportunity cost, as resources that could be directed towards growth and customer acquisition end up being allocated to deal with the consequences of corrosion.

Another equally relevant aspect is the potential impact on the company’s reputation. Corrosion not only affects our production line but also the trust our customers place in us. A single incident can undermine years of hard work building a solid image.

The sum of these factors leads specialists to claim that losses due to corrosion can, in some cases, exceed 30% of profitability, depending on the industry sector.

However, it’s important to clarify that I am not saying there is no solution to minimize corrosion’s impact on the industry. I’ve been working with anti-corrosive solutions for over three decades, and I know their effectiveness. We just need to be mindful that seeking a solution should not result in a new problem.

Financial Corrosion

Many companies incorporate anti-corrosion measures into their production processes. Yet, like corrosion itself, this approach can hide a series of expenses that are not immediately noticeable and that may compromise both productivity and profitability. This is what we can call “profit corrosion.”

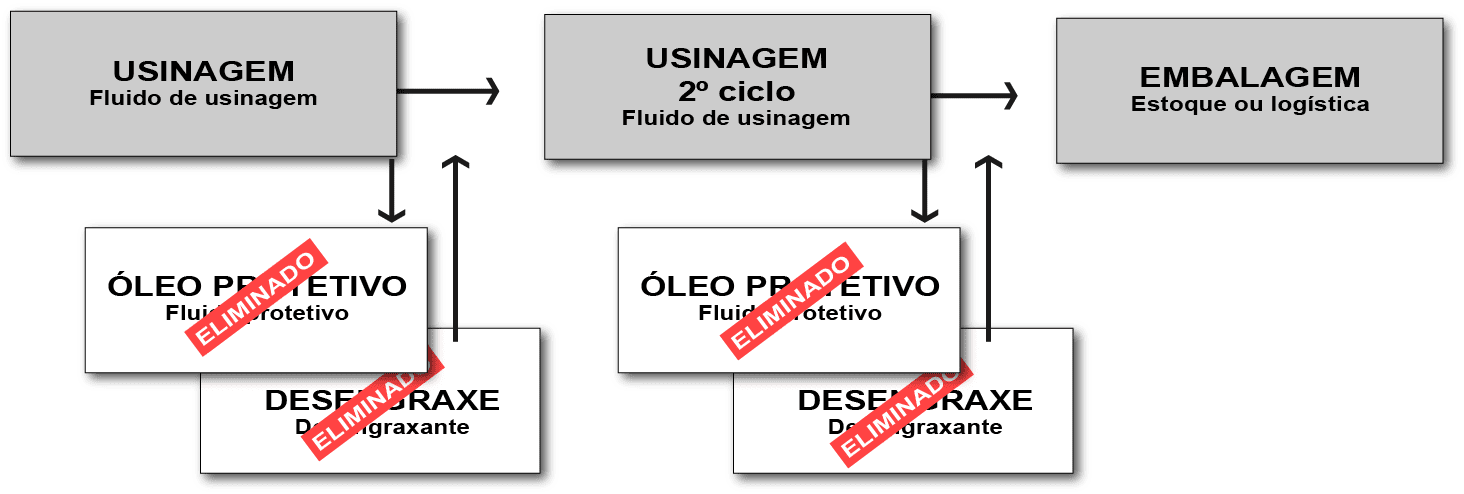

Take, for example, the choice to use a protective oil, a practice adopted by a considerable number of companies. This approach ultimately adds an inefficient cost to the production line. Additionally, machine operating hours and labor will be allocated to this step, possibly requiring more time later on to remove this protective coating, either for subsequent process steps or for logistical management.

An example of a machining process using protective oil is the manufacturing of precision components, such as pistons or cylinders for engines.

At this point, I believe you can already envision the scenario. Adding two steps to your production line will result in a significant reduction in the number of products manufactured daily – imagine dropping from 100 units to 80 per hour. Add to this the cost of professionals dedicated to applying and removing these protectants, along with associated labor taxes and charges, the cost of the protective fluid itself, water and energy consumption in this process, as well as other possible expenses, such as labor and environmental liabilities associated with using this type of product.

This is the process of “corroding” your profits. While this may be consuming a considerable portion of your financial results, know that this situation is avoidable.

The Need for an Innovative Solution

In a context like this, the need for a different solution arises—a smarter, more integrated vision.

This type of challenge has driven VCI Brasil for more than 30 years in the pursuit of innovative and efficient corrosion prevention solutions. Our V-active technology is concrete proof of this. Our fluids not only protect against corrosion but also eliminate unnecessary steps, optimizing resources and reducing costs.

The V-Active technology allows the creation of 3-in-1 solutions for machining and cleaning processes (CNC cutting fluids and degreasing fluids), offering multiple benefits in a single operation: machining/cleaning, corrosion protection, and production stage reduction.

It’s also worth noting that, being a water-based solution, V-active technology poses no risk to human health or the environment, reaffirming a commitment to life and avoiding potential labor and environmental liabilities.

The search for smarter solutions is a continuous, shared journey that not only protects our profits but also positions us as vision leaders in our sectors. Want to learn more about our anti-corrosive solutions or continue this conversation? Then get in touch with us.